Product Description:

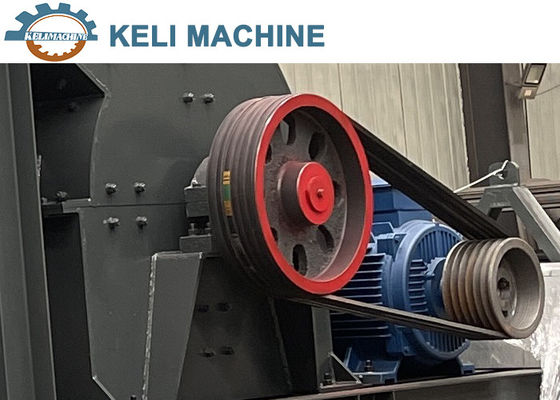

The hammer crusher is composed of multiple parts, the most important of which is the rotor with a hammer.

It is formed by a main shaft, a disk, a pin and a hammer and is driven by a motor to rotate at high speed in the crushing chamber. The materials enter the machine through the upper feeding port and are crushed through the impact, shearing and grinding action of the hammer. In the lower part of the rotor, there is no sieve plate, and the materials with a size which is smaller than the mesh size will be discharged through the sieve plate.

Meanwhile, the coarse-grained materials larger than the mesh size will again be struck and ground by the hammer before being discharged out of the machine through the sieve plate. In addition, the hammer crusher also comprises of a hammer crushing case body, a counter lining plate and some other parts.

Product Feature:

- Fully sealed design, no dust pollution

|

- Uniform output, no flakes

|

- Easy replacement of parts and easy maintenance

|

- Simple structure, reliable operation and easy operation

|

Applications:

This machine is suitable for medium crushing, coarse crushing, and processing of various medium-hard ores and rocks, such as coal, limestone, slag, in construction, electric power, chemical industry, metallurgy, and geological fields.

It is widely used for industrial purposes in different sectors, including mining, power plants, cement production, machine building, and other industries.

Product parameters:

Hammer Crusher

Brand Name: KELI

Model Number: PC300x200

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1set

Packaging Details: Container

Delivery Time: 15-35days

Payment Terms: L/C, T/T

Supply Ability: 100sets/month.

Capacity: 1-5 Ton/Hour

Power: 5.5kw

Feed particle size: 100mm

Type: Hammer Crusher

Machine weight: 200kg

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!